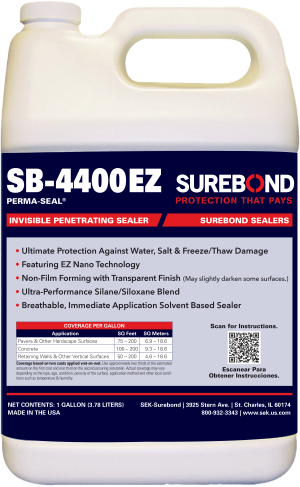

SB-4400 EZ Perma-Seal®

Invisible Penetrating Sealer

- Chemically Bonded Ultimate Protection: Deep Surface Penetration, Superior Longevity & Durability

- Silane/Siloxane Solvent-Based Blend: Excellent Water Repellency & Safeguards Surface from Salt Attack

- Non-Film Forming with Transparent Finish: Does Not Alter the Appearance of Most Surfaces

- Breathable, Immediate Application: Does Not Trap Moisture or Efflorescence

SB-4400 EZ Perma-Seal® is a solvent-based silane/siloxane invisible penetrating sealer. It is recommended for outdoor use, on old and new, horizontal or vertical surfaces. SB-4400 EZ can be applied immediately after most surface installations, as it is breathable and will not trap naturally occurring moisture or efflorescence. On new concrete, SB-4400 EZ should be applied once concrete is fully cured (30 days after installation). SB-4400 EZ protects surfaces from water penetration and salt damage from the use of de-icers or exposure to salt air. Due to its superior water repellency, SB-4400 EZ helps to reduce biological growth such as mold, moss and algae. SB-4400 EZ has the consistency of water, is clear when applied and dries transparent on most surfaces. Some surfaces may darken slightly. Cured sealer is freeze resistant to -60°F (-51°C) and is stable up to a temperature of 180°F (82°C).

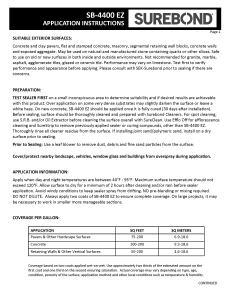

Suitable Surfaces

Suitable for concrete and clay pavers, flat and stamped concrete, masonry, segmental retaining wall blocks, concrete walls and exposed aggregate. May be used on natural and manufactured stone containing quartz or other silicas, grout, unglazed tile and terra cotta. Safe to use on old or new surfaces in outside environments. Not recommended for granite, marble, asphalt, glazed or ceramic tile. Performance may vary on limestone. Test first to verify performance and appearance before applying.

A test area is always recommended to determine product suitability and compatibility with your specific surface before use and also if desired results are achievable. SB-4400 EZ may slightly darken some surfaces. Due to the inherent variability of natural stone and clay products, long term performance may vary. Please consult with us prior to sealing if there are concerns.

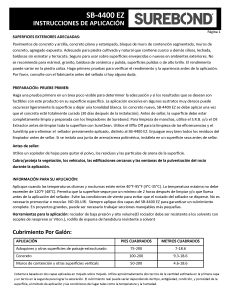

Coverage Per Gallon

| Application | Sq.Feet | Sq.Meters |

|---|---|---|

| Pavers & Other Hardscape Surfaces | 75 – 200 | 6.9 – 18.6 |

| Concrete | 100 – 200 | 9.3 – 18.6 |

| Retaining Walls & Other Vertical Surfaces | 50 – 200 | 4.6- 18.6 |

Coverage based on two coats applied wet-on-wet. Use approximately two thirds of the estimated amount on the first coat and one third on the second ensuring saturation. Actual coverage may vary depending on the type, age, condition, porosity of the surface, application method and other local conditions such as temperature & humidity.

Click below to open up the tab to reveal more information.

SB-4400 EZ Helpful Information

Please visit our video gallery to view all available cleaning, sanding and sealing related videos.

Coming soon.