SB-6700

SurfacePRO Ultra

Two-Part Urethane Wet Look Joint Stabilizing Sealer

- Multi-Purpose Product: Seals & Enhances Surface, Hardens Joint Sand

- Surface Enhancement: Ultra-Deep Enhancement of Surface & Gloss Finish

- Antifungal Film Protection: Protects Sealer Film from Mold, Moss & Algae

- Optimal Joint Sand Stabilization: Reduces Sand Washout, Weeds & Insect Infestation

- Ultimate Durability & Protection: Promotes Easier Cleaning & Maintenance

- Breathable, Immediate Application – Does Not Trap Moisture or Efflorescence

SB-6700 SurfacePRO Ultra is a proprietary water-based, two-part, water reducible, clear (non-yellowing), aliphatic urethane sealer and joint sand stabilizer with ultimate durability. It can be used inside and outside, on old and new, horizontal or vertical surfaces to provide surface protection and stabilize newly installed joint sand in one application process. SB-6700 can be applied immediately after most surface installations, as it is breathable and will not trap naturally occurring moisture or efflorescence. On new concrete, mortar, grout or overlays, it is recommended to wait 7 days after installation to allow for curing before applying SB-6700. Optimal results when performing same day cleaning, sanding and sealing with SB-6700 can be achieved when following the recommended application process. SB-6700 is specially formulated with an antifungal designed to help inhibit the growth of mold, moss and algae on the sealer film. SB-6700 protects the surface from salts, acids and other corrosive chemicals as well as minimizes overall surface weathering and deterioration. On a newly installed or restored surface, SB-6700 will deeply enhance surface tone with an ultra-wet look, gloss finish and provide stain resistance which makes cleaning and maintenance easier. It is non-hazardous and VOC/EPA compliant. SB-6700 is a two component product that requires mixing and dilution before use. Once mixed and diluted, it has the consistency of water, is milky white when applied and dries clear with gloss finish. Cured sealer is freeze resistant to -60°F (-51°C) and is stable up to a temperature of 180°F (82°C).

RECOMMENDED FOR PROFESSIONAL USE ONLY.

WARNING: Once applied, SB-6700 cannot be chemically stripped from the applied substrate. If removal is necessary, sand blasting or other mechanical methods must be used. USE PRODUCT AT YOUR OWN RISK.

Suitable Surfaces

Suitable for concrete and clay pavers, flat and stamped concrete, masonry, natural and manufactured stone, segmental retaining wall blocks, concrete walls and exposed aggregate. Ideal for shaded areas, pool decks and outdoor showers where mildew, fungus and algae are a concern. Recommended for high-traffic areas where high durability and superior chemical resistance is desired. Safe to use on old or new surfaces in both inside and outside environments. Not recommended for granite, marble, asphalt, glazed or ceramic tile. Test first to verify performance and appearance before applying.

A test area is always recommended to determine product suitability and compatibility with your specific surface before use and also if desired results are achievable. Due to the inherent variability of natural stone and clay products, long term performance may vary. Please consult with us prior to sealing if there are concerns.

Coverage Per Gallon Of Mixed & Diluted Product:

| Application | Sq.Feet | Sq.Meters |

|---|---|---|

| Sealing with joint stabilization | 80 – 120 | 7.4 – 11.1 |

| Sealing only without joint stabilization | 200 – 300 | 18.6 – 27.9 |

Coverage is based on single application. Actual coverage may vary depending on type, age, condition, joint size, porosity of the surfaces, application method and site conditions such as temperature & humidity. For more uniform coverage a second coat must be applied after the first coat has dried to the touch.

Click below to open up the tab to reveal more information.

SB-6700 Helpful Information

RECOMMENDED FOR PROFESSIONAL USE ONLY

WARNING: SB-6700 is extremely difficult to chemically strip from the applied substrate. Several applications of AllStrip Sealer Stripper may be required to fully remove sealer from surface. Use product at own risk.

Preparation

TEST SEALER FIRST on a small inconspicuous area to determine suitability and if desired results are achievable with this product. Before sealing, surface should be thoroughly cleaned and prepared with Surebond Cleaners. For spot cleaning, use S.R.B. and/or Oil Extractor before cleaning the surface overall with SureClean. Use Efflo Off for efflorescence cleaning and SureStrip to remove previously applied sealer, other than SB-6700. Remove and kill any mold, mildew, fungus or algae. For joint stabilization in existing surfaces, old joint sand should be removed to a minimum depth of 1” from the top of surface. Thoroughly rinse all cleaner residue from the surface. For applications without joint stabilization, SB-6700 can be applied to a damp surface with NO ponding or pooling of water present. For applications with joint stabilization, allow the surface to dry before sealer application.

Joint Sand Installation: Surface must be dry for ease of installation. Paver joints should be no more than ¾” wide and filled with ASTM C144 joint sand. Vibrate surface with vibratory roller or compactor after sweeping sand into joints to minimize air voids. Sand level should not exceed the bottom of the chamfer edge or 1/8” down from the top on non-chamfered surfaces. Do not use wet joint sand because it will severely diminish joint stabilization.

Prior to sealing: Use a leaf blower to remove dust, debris and fine sand particles from the surface. Cover/protect nearby landscape, vehicles, and buildings from overspray during application.

Full Kit Mixing Instructions

SB-6700 is a two-part product that comes packaged in a kit which contains one five gallon pail of Part A and two one gallon containers of Part B.

Tools Needed:

- Variable Speed Drill

- Paddle Mixer

- One Clean Five Gallon Pail

Mixing Instructions:

- Using the SB-6700 Marking Label as a guide (found on Part A five gallon pail), mark the PART A LINE on a clean five gallon pail.

- Pour half of Part A into the 5 gallon pail up to the PART A LINE. Contents of both pails should be at the PART A LINE.

- Blend one container of Part B into one pail containing Part A with a drill and paddle mixer on low speed for 1-2 minutes. Do not whip air into the mixture.

- Repeat step 3 with the remaining container of Part B and the remaining five gallon pail containing Part A.

SB-6700 Mixture (combined Parts A and B) has a pot life of 90 minutes which varies based on temperature and humidity. Do not mix more material than can be used in a 90 minute period. Do not store SB-6700 Mixture. If less than the entire kit is needed, see Project Calculator for more information.

SB-6700 Dilution Instructions

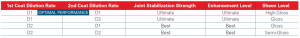

Before application the SB-6700 Mixture must be diluted with water following one of two recommended dilution rates: D1 or D2. Choose the dilution rate that will produce the desired level of joint stabilization, enhancement and sheen. When applying the recommended two coats, the dilution rate of each coat can be the same or different based on the desired outcome. See chart below to assist in selecting the appropriate dilution level for the project. The use of any dilution rate other than D1 or D2 is not recommended.

Tools Needed:

• Variable Speed Drill

• Paddle Mixer

• One or Two Additional Clean Five Gallon Pails (Quantity varies based on desired dilution.)

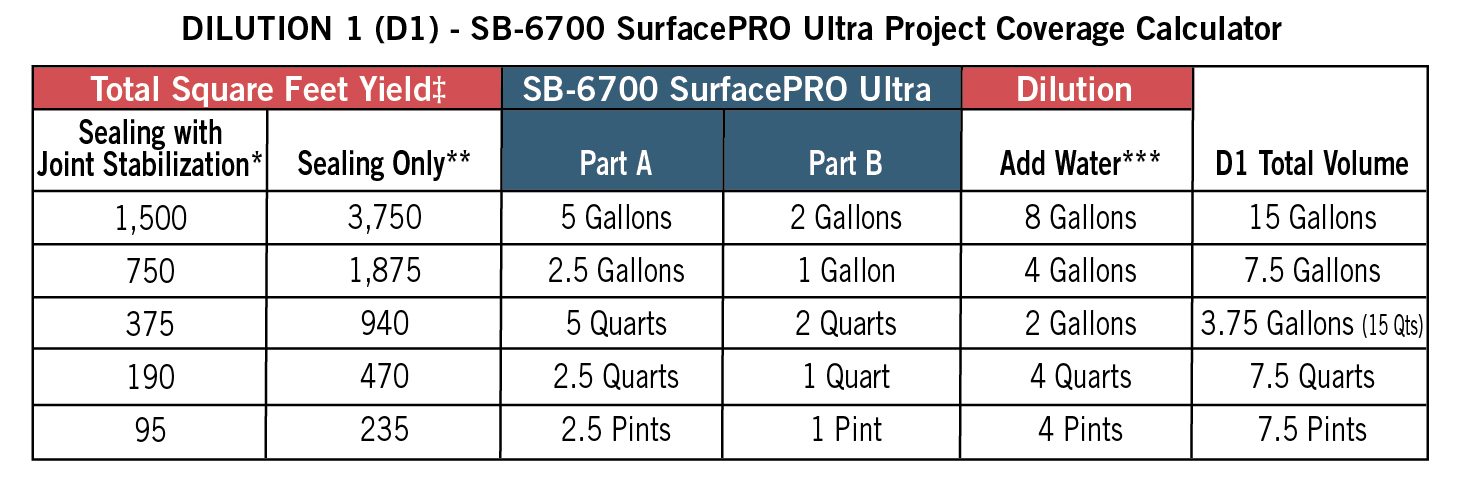

1:1 Dilution Ratio (D1):

Suitable on all surfaces to create a high-gloss sheen with optimal joint sand stabilization. Can also be used as a sealer without joint stabilization.

Yields 15 gallons of ready to use SB-6700.

Full Kit D1 Dilution Instructions:

- Before diluting, use the SB-6700 Marking Label as a guide (found on Part A pail), mark D1 on one empty five gallon pail and on the second mixture pail that isn’t labeled.

- Pour approximately a third of the SB-6700 Mixture from each pail into the empty pail. The contents of all three pails should now be at the D1

- Fill each pail to the top rib (1.5″ down from the top of pail) with water.

- Using a drill with paddle mixer, mix on low speed for 1 – 2 minutes. Do not whip air into the dilution.

* Coverage rate used for joint stabilization – 100 SF per gallon.

** Coverage rate used for sealing – 250 SF per gallon.

*** Add water to make total volume

‡ Single Application. Actual coverage may vary depending on the type, age, condition,

joint size and porosity of the surface, application method and site conditions such as temperature.

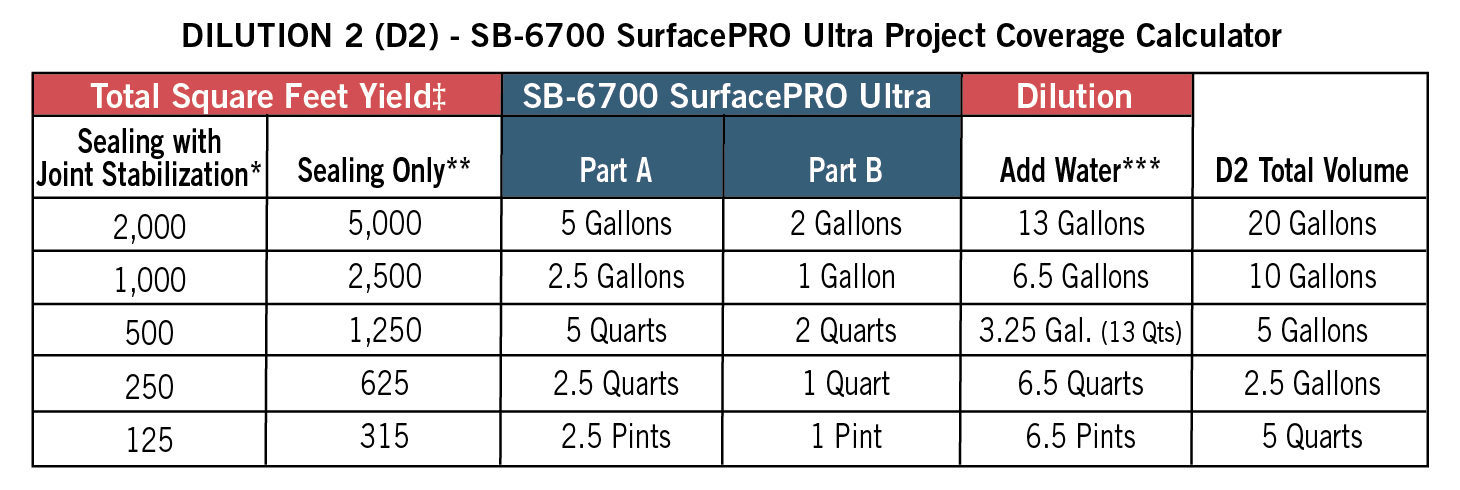

2:1 Dilution Ratio (D2):

Suitable on all surfaces to create a satin/semi-gloss sheen with great joint sand stabilization. Can also be used as a sealer without joint stabilization.

Yields 20 gallons of ready to use SB-6700.

Full Kit D2 Dilution Instructions:

- Before diluting, use the SB-6700 Marking Label as a guide (found on Part A pail), mark D2 on two empty five gallon pails and on the second mixture pail that isn’t labeled.

- Pour approximately a half of the SB-6700 Mixture from one of the mixture pails into one of the empty pails.

- Repeat step 2 with remaining pail of SB-6700 Mixture and the remaining empty five gallon pail. The contents of all four pails should be at the D2 line.

- Fill each pail to the top rib (1.5″ down from the top of pail) with water.

- Using a drill with paddle mixer, mix on low speed for 1 – 2 minutes. Do not whip air into the dilution.

* Coverage rate used for joint stabilization – 100 SF per gallon.

** Coverage rate used for sealing – 250 SF per gallon.

*** Add water to make total volume

‡ Single Application. Actual coverage may vary depending on the type, age, condition,

joint size and porosity of the surface, application method and site conditions such as temperature.

Application

Apply when day and night temperatures are between 40°F – 95°F. Maximum surface temperature should not exceed 120°F. To cool hot surfaces, mist with water without ponding or pooling prior to applying SB-6700. Avoid windy conditions to keep sealer spray from drifting. SB-6700 is a two part product: read and follow the Mixing and Diluting Instructions before applying. Use product coverage calculators to determine the amount of material required for the project; material coverage will depend on the surface type and its porosity. Excessive applications may decrease breathability and/or cause surface to become slippery. Some surfaces, such as travertine, pool decks and very smooth substrates, may require an anti-slip additive to increase friction. On large projects, it may be necessary to work in smaller more manageable sections.

Application Tools: low pressure high volume sprayer, slit foam roller, foam squeegee for joint stabilization

Spray & Back Roll Application (no joint sand stabilization): Use coverage rate for sealing without joint stabilization. Hold sprayer nozzle perpendicular to the surface, spray and overlap each spray pass. Saturate the surface to ensure proper coverage. Do not apply too thick to avoid air bubbles in the sealer film. Before sealer dries, back roll surface with a foam roller to eliminate any pooling and to even out the sealer. For optimal performance a second application should be applied. Second coat should be applied as soon as practical after the first application has visually cleared and is dry to the touch, which is usually within one hour. Second application must be applied prior to full cure (see Dry Time for more information). With interior applications, SB-6700 may be carefully sprayed or applied with a slit foam roller taking care not to roll back and forth excessively.

Flood Coat & Squeegee Application for Joint Stabilization: Use coverage rate for sealing with joint stabilization. Liberally spray sealer to flood surface and joints ensuring proper sand penetration for stabilization. Saturate the surface to ensure proper coverage. Do not apply too thick to avoid air bubbles in the sealer film. Use a foam squeegee to direct excess sealer into joints. On an uneven surface, it is recommended to then back roll with a slit foam roller to even out the sealer and eliminate pooling. For optimal performance a second application should be applied. Second coat should be applied as soon as practical after the first application has visually cleared and is dry to the touch, which is usually within one hour. Second application must be applied prior to full cure (see Dry Time for more information).

NOTE: To minimize slipperiness on travertine, pool decks and very smooth surfaces, use an anti-slip additive with both D1 and D2 applications.

Dry Time

Surface will be dry to the touch within 1-2 hours assuming 65-85°F at 50% relative humidity. Low surface or air temperature and or high relative humidity will extend dry times. Protect the surface from dust, rain, condensation and traffic while drying. Full cure will take 24 – 36 hours depending on weather and site conditions. After surface has visually cleared and is dried to the touch, area can be open to foot traffic in 24 hours and vehicular traffic in 48 hours depending on weather and site conditions.

Clean Up

For tools and equipment, clean with soap and water before product is allowed to dry.

Please visit our video gallery to view all available cleaning, sanding and sealing related videos.