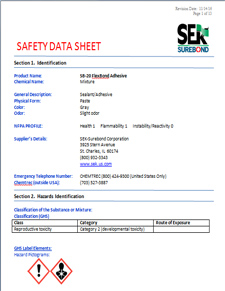

SB-20 Flex-Bond Adhesive

High Strength Silicone/Polyurethane Hybrid Adhesive

Specifically designed for demanding applications requiring a flexible bond

- High Strength Adhesion

- Flexible & Durable

- VOC Compliant

SB-20 Flex-Bond is a high strength hybrid adhesive combining the flexibility of silicone and the bond strength of polyurethane. Its solvent free formula provides superior durability to withstand the most extreme service conditions. SB-20 Flex-Bond’s high viscosity helps you level and shim coping and caps. Applies easily with a standard caulking gun to unfrozen surfaces, wet or dry. SB-20 Flex-Bond’s moisture cure system achieves full cure in 24 hours.

Uses

Ideal for retaining walls, seat walls, columns, caps, steps and outdoor kitchens where a flexible bond is beneficial.

Suitable Surfaces

Suitable for concrete and clay pavers, coping systems, masonry and brick, natural and manufactured stone, slate and porcelain tile. Also bonds to other building materials such as PVC, glass, aluminum, painted surfaces, wood and metal.

Coverage*

| Bead Size | 10.3 fl. oz. | 28.0 fl. oz. |

|---|---|---|

| 1/8" bead | 103 linear feet | 288 linear feet |

| 1/4" bead | 26 linear feet | 86 linear feet |

| 3/8" bead | 13.5 linear feet | 38 linear feet |

*Actual coverage may vary depending on substrate type, age, condition, as well as application method.

Click below to open up the tab to reveal more information.

SB-20 Flex-Bond Helpful Information

PREPARATION

Before application, inspect pavers or stone to ensure they are smooth, flat and of the same height. Substrate must be structurally sound with no spalling, cracking or scaling. For ultimate adhesion, surface should be clean, free from dirt, oil and grease, excessive water, ice or any other material. If cleaning is required, prepare surface with SureClean Deep Penetrating Multi-Use Cleaner. Rinse thoroughly. To ensure final assembly, dry fit all pieces prior to applying SB-20 Flex-Bond. Proper drainage must be provided so that water does not drain into and collect in adhered areas.

APPLICATION INFORMATION

Cut nozzle to desired size and puncture inner seal. Apply a 1/8” to 3/8” bead of SB-20 Flex-Bond using a caulking gun. On most applications, apply SB-20 Flex-Bond in an ‘S’ shape bead. Where there is a potential for moisture infiltration, apply multiple lines of SB-20 Flex-Bond parallel with the drainage flow. Set substrate in place and tamp gently with a rubber mallet to compress the adhesive. Positioning and aligning should be done within 15-20 minutes of application.

DRY TIME

SB-20 Flex-Bond skins over at 30 minutes and initial set up time is 45 minutes. Full cure is achieved at a rate of 1/8” thickness per 24 hours. Cure rate will vary slightly with ambient conditions. Fully cured, SB-20 Flex-Bond is non-flammable and non-toxic.

CLEAN UP

Use general purpose detergent/soap solution or any other biodegradable cleaner to clean up tools or excess product from substrate. Care should be used to follow manufacturer’s instructions and precautionary information.

SEK-Surebond warrants its products to substantially conform to its published specifications at the time of purchase. The foregoing is the sole limited warranty applicable to the products. SEK-SUREBOND HEREBY DISCLAIMS ALL OTHER WARRANTIES OF ANY KIND OR NATURE, WHETHER EXPRESS, IMPLIED, OR STATUTORY, INCLUDING WITHOUT LIMITATION THE IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, OR ANY OTHER WARRANTY OTHER THAN THE WARRANTY SET FORTH ABOVE. The user is solely responsible for determining suitability of the products for their particular use. While the actual application of this product is out of the control of SEK-Surebond, it is recommended that the application guidelines be followed completely and accurately. SEK-Surebond’s liability for any damage shall not exceed the purchase price of the product used, and it shall have no liability for consequential, incidental or punitive damages.